1 引言

为满足电动汽车高电压和大容量的需求,电池单体采用最常见的串并联相结合的方式进行使用[5]。在电动汽车运行或充电过程中,电池处于充放电的环境,此时电池温度会发生很大的变化。若不及时散热,热量在电池模块内持续积累,会导致电池模块热量不断上升和不均匀扩散。锂电池内部化学成分耐热性较差,因此在高温下会加速反应,导致锂离子电池内部结构产生质变,最终造成严重的安全后果。同时,锂电池也不适合在低温环境下工作,低温下锂电池的活性会下降[6]。因此,需要一个高效的电池热管理系统(Battery thermal management system,BTMS)来保持适当的电池工作温度范围,以防止温度过高或过低所带来的不利影响[7]。一般来说,电池温度每升高10 ℃,内部化学反应速率增大一倍,其寿命减少一半。通过对容量为1.8 A·h的索尼18650锂电池的循环性能进行研究,结果表明,在25 ℃和45 ℃工作温度下锂电池进行800次充放电循环后,电池容量分别下降31%和36%;当工作温度为50 ℃时,500次充放电循环后电池容量下降60%[8]。对于锂电池,工作温度超过50 ℃,电池的使用寿命就会随之下降。电池的容量和功率可以用来表征电池性能的优劣[9],高温下由于锂电池内部的活性物质发生死区和析锂现象,导致电池的容量减少,而电池功率也因阻抗增加而降低[8,10⇓⇓⇓ -14]。表1总结了锂离子电池容量衰减和温度的关系,得出锂电池最佳工作温度范围是25~40 ℃。

表1 锂离子电池容量在不同温度条件下的衰减总结

| 作者 | 电池阴极/阳极 | 放电电压范围/深度 | 循环倍率 | 循环次数 | 温度/℃ | 容量衰减(%) |

|---|---|---|---|---|---|---|

| RAMADASS等[8] | C/LiCoO2 | 4.2~2.0 V | C/9~C/1 | 500 | 55 | 70.56 |

| 25 | 22.5 | |||||

| 800 | 45 | 36.21 | ||||

| 25 | 30.63 | |||||

| ZHANG等[11] | C/LiFePO4 | 3.6~2.0 V | 3C | 600 | 45 | 25.6 |

| 25 | 14.3 | |||||

| 0 | 15.5 | |||||

| -10 | 20.3 | |||||

| LIU等[12] | C/LiFePO4 | 90%DOD | C/2 | 757 | 60 | 20.1 |

| 2 628 | 15 | 7.5 | ||||

| 50%DOD | C/2 | 1 376 | 45 | 22.1 | ||

| JAGUEMONT等[13] | C/LiFeMnPO4 | 60%DOD | 1C | 170 | 25 | 7 |

| -20 | 20.8 | |||||

| ZHENG等[14] | C/LiFePO4 | 70%DOD | 1/3C | 100 | -10 | 12.77 |

| 100%DOD | 1C | 20 | 30.69 | |||

| 40 | 29.33 |

随着电动汽车的发展和动力系统功率的不断提升,电池组的密度也比以往增加更多,快速充电的需求导致电池在大电流充放电时产生更多的热量。在这种趋势下设计出合理的电池热管理系统成为焦点,需要在高温下进行快速散热、低温条件下能够进行加热或保温,以提升电动汽车的整体性能。

电池热管理系统可分为电池散热系统和电池加热系统,本文重点讲述电动汽车锂电池的散热系统。

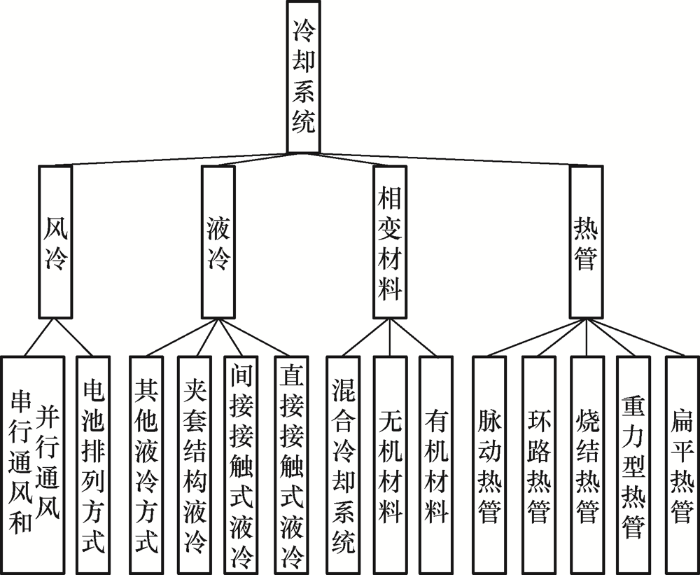

图1

本文第2节论述了锂电池的产热原理及模型,第3节详细介绍锂电池不同散热系统的性能和优缺点。最后在第4节进行总结并对未来的散热技术发展方向做出了展望。

2 锂电池产热原理及模型

2.1 电池产热原理分析

以锂离子电池为例,其产热来源主要有三种形式[21],分别为极化热$({{Q}_{p}})$、内阻焦耳热$({{Q}_{j}})$和化学反应热(${{Q}_{r}}$)。

(1) 极化热。电池极化主要包括活性极化和浓差极化,在充放电过程中取正值。极化热公式为

式中,$J_{i}^{Li}$为锂离子交换的电流密度,${{\eta }_{i}}$为过电势,$I$为电池充放电电流大小,${{R}_{p}}$为电池极化内阻。

(2) 内阻焦耳热。内阻焦耳热是电池充放电过程中最主要的热量来源。该值始终为正值,充放电过程中都产生热量,公式如下所示

式中,${{R}_{\varphi }}$为电池内阻之和。

(3) 化学反应热。化学反应热为锂电池内部因锂离子的活动而产生的热量,在放电时热量取正值,充电时取负值。反应热公式为

式中,$H$为焓(J),$S$为熵(J/K),$G$为吉布斯自由能(J),$\text{ }\!\!\Delta\!\!\text{ }G=\text{ }\!\!\Delta\!\!\text{ }H-T\text{ }\!\!\Delta\!\!\text{ }S$,$T$为热力学温度(K),$n$为电子数,$F$为法拉第常数。

因此锂电池总产热量可以表示为

电池平均产热速率可用$V$来表示

式中,$Q$为电池工作时间总的产热量(J),$t$为电池工作时间(s)。

2.2 电池热数学模型

电热模型最初是由美国国家可再生能源实验室的Steve BURCH提出,后由JOHNSON[30]改进,模型的散热量计算为

式中,${{R}_{eff}}$为有效热阻,即

式中,$h$为表面换热系数,由电池的温度决定,即

式(6)中电池周围的温度${{T}_{air}}$为

利用锂离子电池的热滥用三维模型来模拟电池热模型[31],模型的热源为

式中,${{q}_{joul}}$和${{q}_{combustion}}$分别表示焦耳热与反应热,${{q}_{abuse}}$为热滥用发生后额外的产热量,${{q}_{sei}}$为SEI分解反应产热,${{q}_{ne}}$为负极活性材料反应热,${{q}_{pe}}$为正极活性材料反应热,${{q}_{ele}}$为电解液分解反应热,${{q}_{nb}}$为正负极之间的反应热。计算公式如下所示

式中,$i=sei,ne$时,$x=c$,${{W}_{c}}$为特定体积的比碳含量;$i=pe$时,$x=p$,${{W}_{p}}$为特定体积的正活性成分;$i=ele$,$x=e$,${{W}_{e}}$为特定体积的电解质含量;${{R}_{i}}{{A}_{i}}{{E}_{a,sei}}{{E}_{a,ne}}{{E}_{a,pe}}{{E}_{a,ele}}$为反应参数,${{H}_{i}}$为比热释放量,${{c}_{sei}}$为SEI中稳定的锂离子无量纲数量,${{c}_{neg}}$为碳中锂离子无量纲数量,${{t}_{sei}}$为SEI中锂离子的数量,$\alpha $为转换度,${{c}_{ele}}$为电解质的无量纲浓度。

该三维模型主要侧重于电池产热骤增情况下的热失控行为,尤其是电池内部的热化学反应机制。

3 锂电池散热系统

散热系统能够使电动汽车以最佳状态运行,为确保锂电池的安全性、使用寿命和性能,需要对电池的温度进行实时监测和及时降温以避免动力电池的热失控。以下将对电池散热的几种不同方式进行详细介绍。

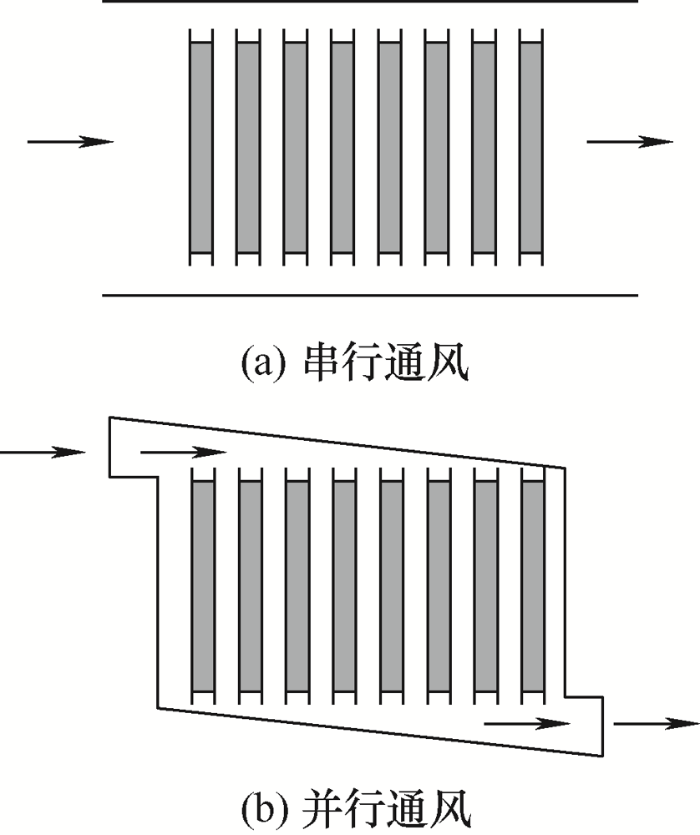

3.1 空气冷却系统

空气冷却又称为风冷,是目前使用最广泛的电池散热方式,可与整车的行驶特性设计相结合。可通过车速形成的自然风将热量带走,也可通过风扇运转产生强制气流。自然对流具有简单易行、低成本、散热过程多以自然对流为主等优点,缺点为风力不可控。强制对流相比自然对流更可靠,更易于维护,因此成为常见的电池冷却方式。强制对流的缺点是电池内的温度分布不均匀,由于空气本身的特性,冷却效果有一定的局限性。

3.1.1 电池排列方式

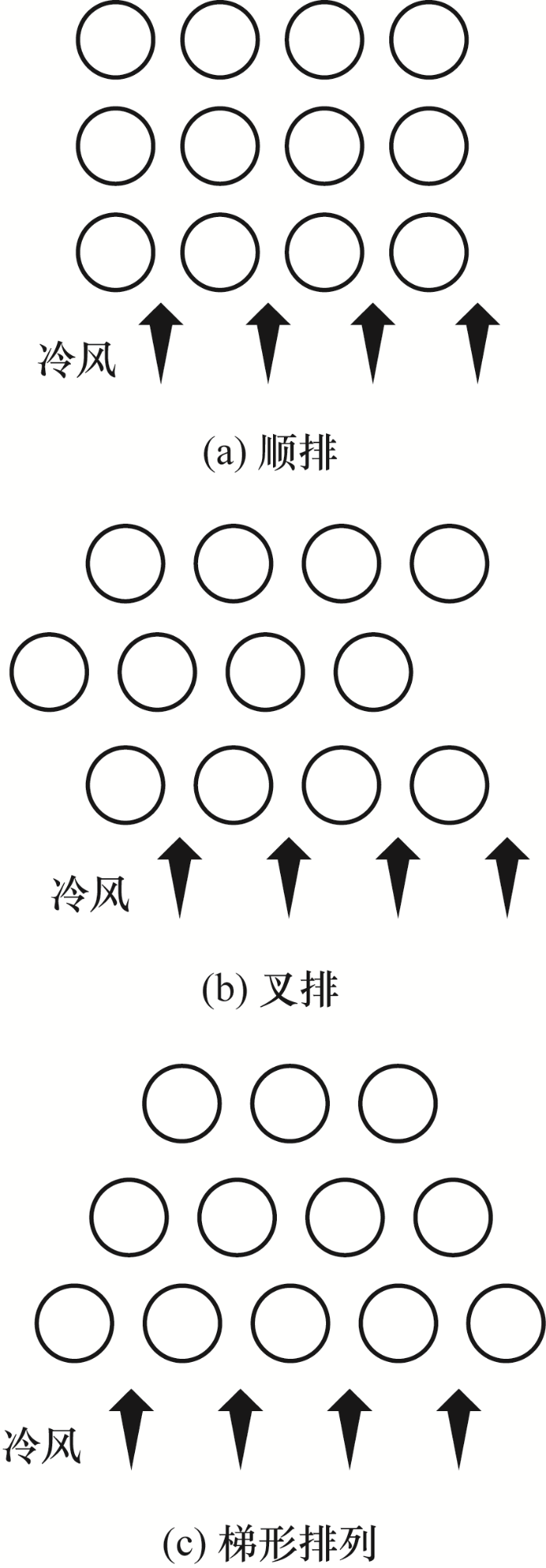

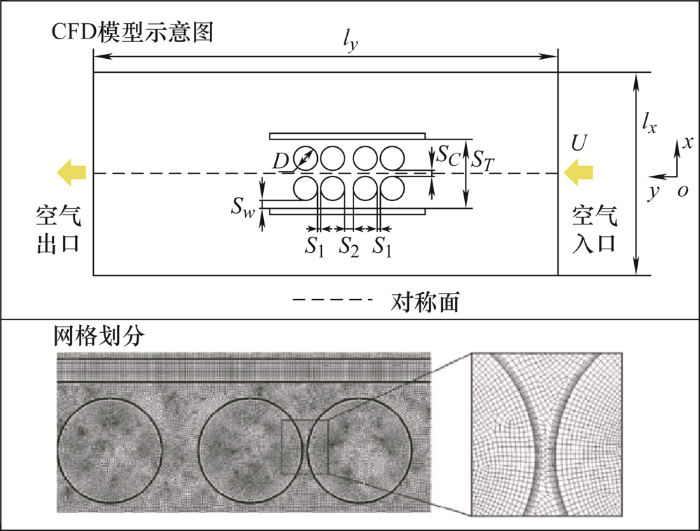

图2

顺排方式为单体电池在电池箱内呈整齐有序的排放,如图2a所示。外部冷空气从电池缝隙穿过,优点为气流阻力较小,缺点为不易受到扰动而产生湍流漩涡,与电池接触面较小,对流换热较小,因此散热效率不高,一般不采用。

图3

该结果与文献[32]截然不同,在电池组中顺排方式表现出更好的冷却性能,其次是交错排列,最后是交叉排列。

通过上述两个风冷热管理散热性能的试验结果对比可知,电池组的排列顺序、进出风口的位置以及风速的大小等因素都会影响电池的散热效果。电池组个数较少时,风速的提高和电池组的排列顺序对散热的性能和温度分布的均匀性影响变化不大。当电池组个数较多、电池包密度较大时,三种排列方式上下游风压的不同会导致每种方式的散热效果呈现出不一致性,甚至会因风速的增加加剧风冷系统能量的二次消耗,与提高电池组效率和散热性能相矛盾。

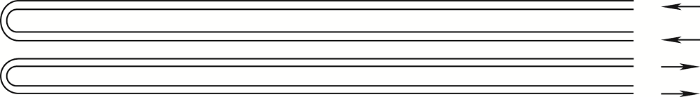

3.1.2 串行通风与并行通风

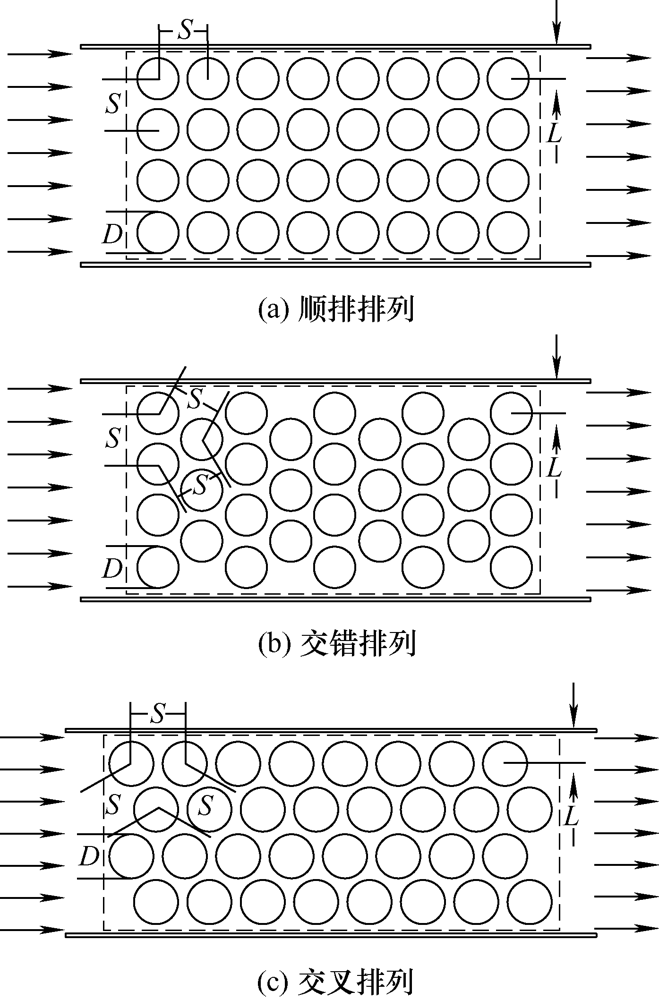

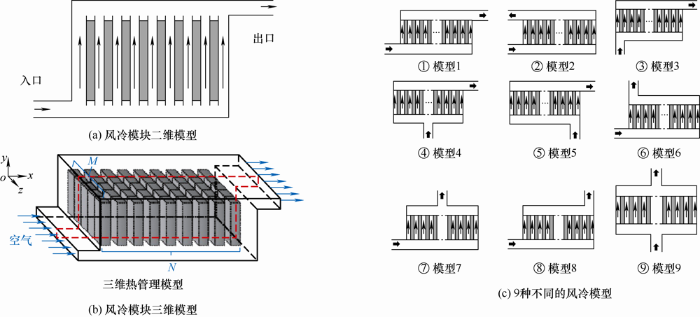

单体电池间的温度差异与其在电池组内的位置有很大关系,一般情况下,下边缘位置相对于中心位置散热较好,温度较低。因此在布置散热设计时,应尽量保证单体电池的温度均匀性。根据通风方式,可分为串行通风和并行通风,如图4所示。

图4

图5

图6

基于风冷热管理的优缺点包括:运行过程中的安全性与可靠性、所需材料简单且易于实现、产生有害气体时能够及时有效通风;与液体和相变材料相比,空气作为冷却介质的降温能力明显不足,且仅适用于低密度电池。表2对风冷系统中的一些重要参数进行了总结。

表2 风冷系统的进展总结

庞大电池组产生的热量使得主动式风冷系统随之增加体积,从而影响电动汽车的性能和乘客的舒适度。为解决风冷系统面临的问题并提高其性能,众多学者开始研究将其他冷却介质加入到风冷系统中。

3.2 液体冷却系统

与基于风冷的电池热管理系统相比,基于液体的热管理具有更高的传热系数和比热容,对提高电池组能量密度和热管理能力有着更显著的效果。表3为水在不同温度下的导热系数。根据电池与冷却液接触的方式,液冷系统可分为直接接触式和间接接触式两种。根据电池液冷散热的结构又可分为主、被动两种方式,被动式系统中,冷却液与外界空气进行热量交换,将电池热量送出;主动式系统中,电池热量通过液-液交换的方式送出。

表3 不同温度下水的导热系数

| 温度/K | 导热系数/[W/(m2·K)] | 温度/K | 导热系数/[W/(m2·K)] |

|---|---|---|---|

| 275 | 0.560 6 | 325 | 0.644 5 |

| 280 | 0.571 5 | 330 | 0.649 9 |

| 285 | 0.581 8 | 335 | 0.654 6 |

| 290 | 0.591 7 | 340 | 0.658 8 |

| 295 | 0.600 9 | 345 | 0.662 4 |

| 300 | 0.609 6 | 350 | 0.665 5 |

| 305 | 0.617 6 | 355 | 0.668 0 |

| 310 | 0.625 2 | 360 | 0.670 0 |

| 315 | 0.632 2 | 365 | 0.671 4 |

| 320 | 0.638 7 | 370 | 0.672 3 |

3.2.1 直接接触式冷却

3.2.2 间接接触式冷却

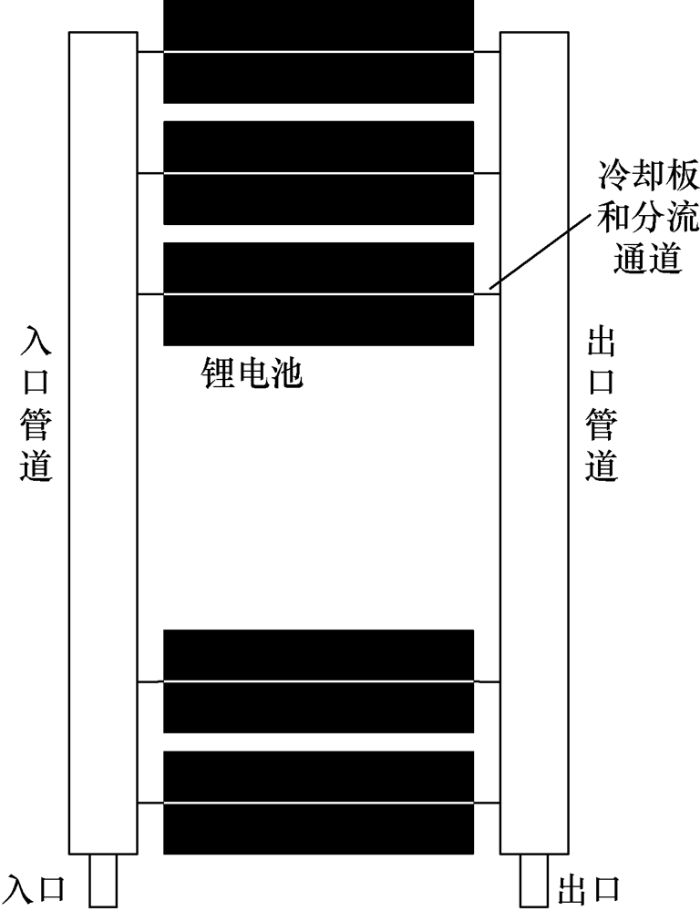

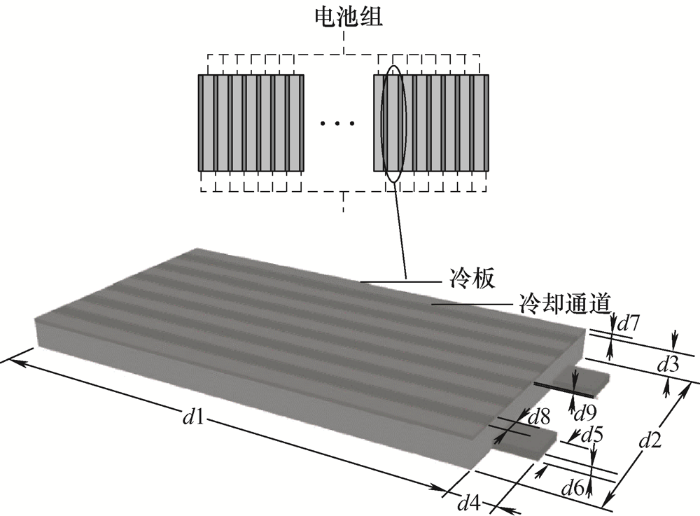

间接接触式冷却系统是通过装有冷却液的翅片或热沉等物质与电池接触带走热量,从而达到使电池降温的目的。对于圆柱形电池,可设置成环形夹套式结构,其液体的流速不受限制,因此可使用导热率高的液体材料。间接接触式冷却系统总体结构如图7所示,液管设置在电池周围通过液体流动进行热量传递。

图7

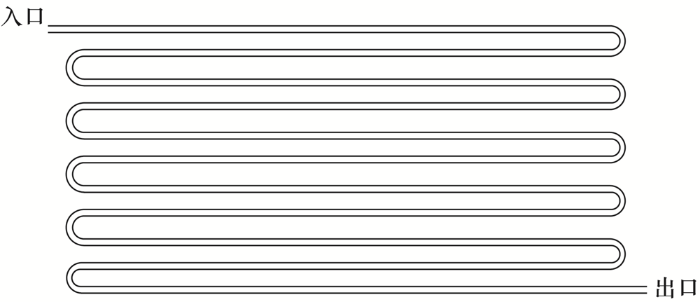

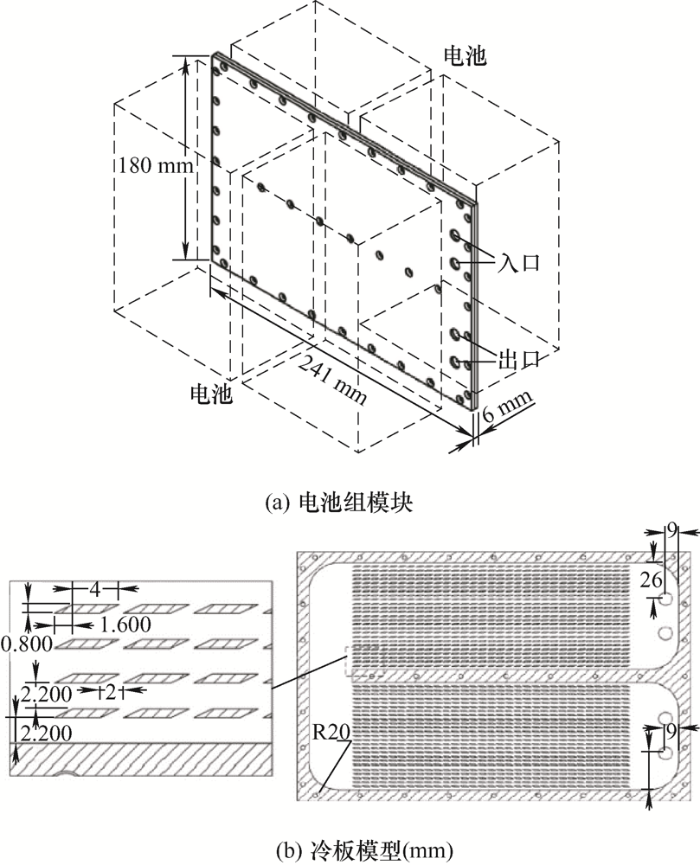

(1) 单进式冷板。与圆柱形电池相比,方形电池形状整齐,表面平整,在相邻电池单体之间可以通过插入板式散热组件,在冷板上焊接各种形状的管道,使液体从管道内流过,对电池进行冷却。也可采用扁平管式结构,将压平的管道置于相邻电池之间。

图8

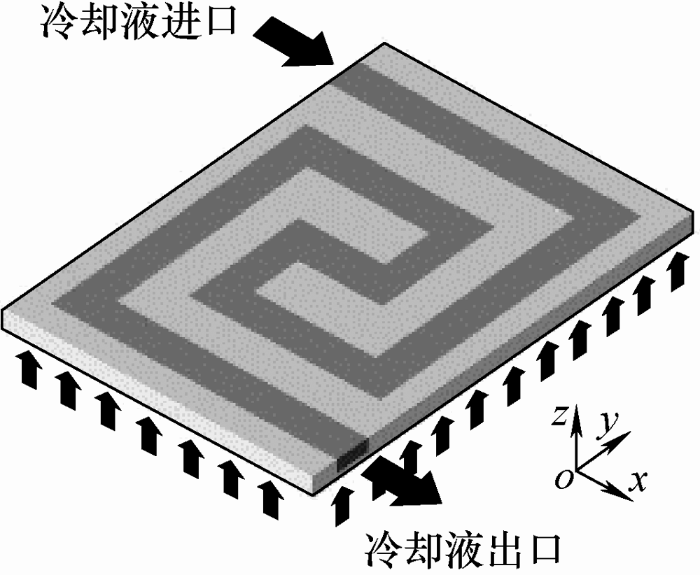

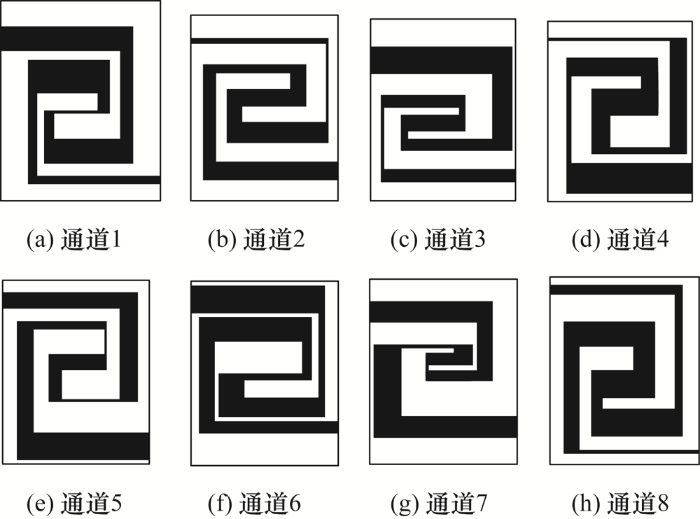

(2) 多进式冷板。多进式通道冷板液冷系统中,冷却液进出口均为两个及以上,如图9所示。当电池尺寸较大或者电池密度较高时,采用单进式通道,冷却液流速越大,电池温差越小,但同时压力耗能也就越大。为减小液体流动时的阻力,研究者们采用了多进多出式通道冷板。多进多出式冷板的优点为冷却速度快、效率高,缺点为进出口的设置越多,复杂程度就越大,同时漏液的可能性就越大。

图9

图10

由于仅采用液态水来作为冷却液材料,当环境温度极其恶劣时难以保证电池的正常使用,需要考虑其他的替代方法或者结合主动制冷以降低通道口的进液温度。

图11

图12

(4) 超薄翅片微型通道冷板。在传统的直通冷板中,冷却液沿着入口端流动到出口端,对流传热系数逐渐降低,导致最高温度持续升高,温度梯度变大。针对此问题,JIN等[43]设计了一种超薄内斜翅片微型通道冷板,当流量和负载分别为0.1 L/min、220 W和0.9 L/min、1 240 W时,该系统能够使电池两边冷板的温度降低到50 ℃以下。

图13

冷板中的斜翅片可使电池内部的热量加速扩散到流动中心,使两端的对流换热系数高于中心的对流换热系数,从而使斜翅片微型通道冷板具有更好的对流传热系数,且冷却液的流动比直通道下的更加均匀。

3.2.3 夹套结构液冷

在电池外套上一层环形腔体,使电池与外壳间构成流体通道,称为夹套式液冷系统。夹套式液冷系统能够满足多种情况下的电池散热情况,甚至可在低温环境下对电池组进行加热。电池组夹套式液冷系统结构由电池组、套管式换热器和管道等组成。

图14

3.2.4 其他液冷系统

液冷散热系统能够有效降低电池的工作温度和局部温差,但同时也存在系统结构复杂,或发生漏液等不良情况。为此TANG等[45]对液冷系统和热泵空调系统(Heat pump air conditioning system,HPACS)进行了耦合设计,建立了基于液冷与热泵空调系统的自动校准模型。通过模型试验表明,设计的液冷系统在环境温度为42 ℃时,入口处的温度可降低至19.8 ℃,此时系统性能参数为2.36。

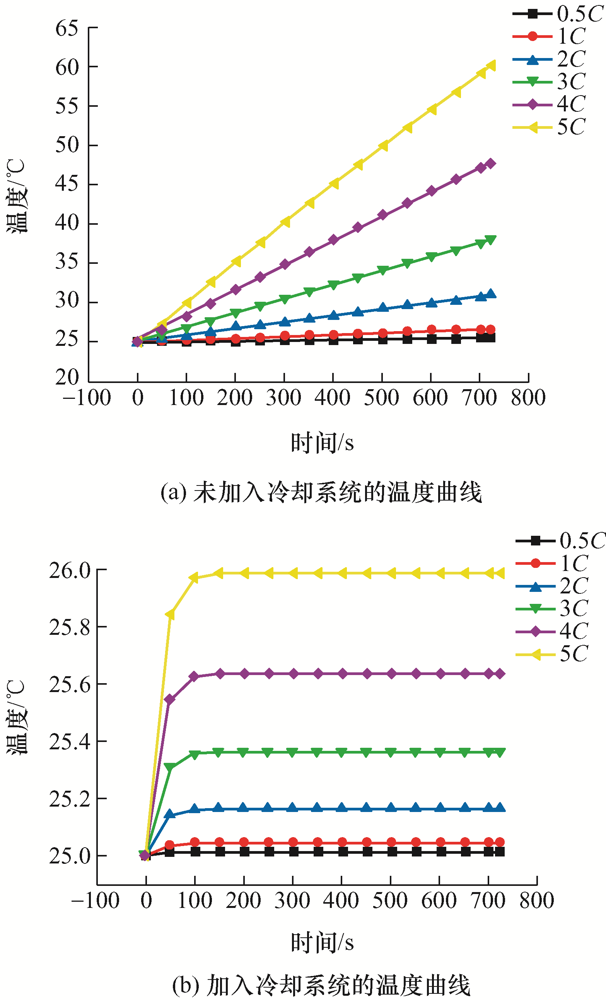

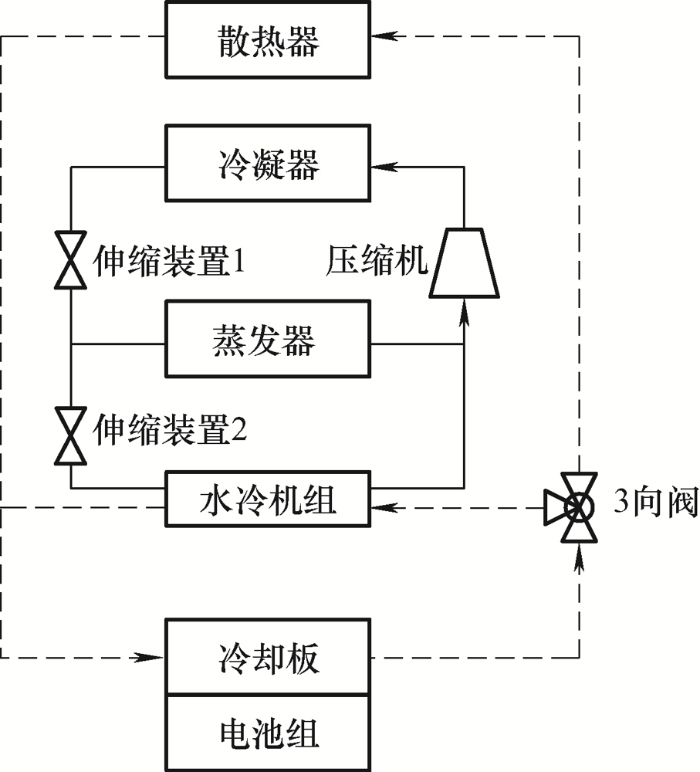

由于空气的传热系数相对较低使得风冷系统不适用于大部分的高性能电动汽车,为克服空气冷却的缺点,可应用二次回路液冷系统。二次回路液冷系统示意图如图15所示[46]。该系统由两个循环组成,虚线表示的制冷剂回路与实线表示的液体冷却剂回路由冷水机连接,液体冷却剂的流量和流速由冷负荷和周围环境来决定,并通过三通膨胀阀控制。当电池需要低冷却性能或环境温度低于液体冷却剂温度时,液体冷却剂就会流向外部的散热器;当电池需要高冷却性能或环境温度高于冷却剂温度时,冷却剂就会流向冷凝器与制冷剂进行热交换。该系统优点为在极端气候条件下还可保持电池适当的温度并满足充放电要求,缺点为该系统结构复杂,随之产生更多重量,增加维护工作量和液体泄漏等风险。

图15

液冷散热系统效果良好,能够有效降低电池的工作温度和局部温差,同时也存在系统结构复杂,质量相对大,存在漏液以及常常需要维护等不利影响。但在对电池工作条件要求相对严格、热管理优先的电动汽车热管理系统中,液冷系统电池散热方式具有比风冷更明显的优势,表4在上述文献和调研的基础上对散热性能进行了总结。

表4 液体冷却系统总结

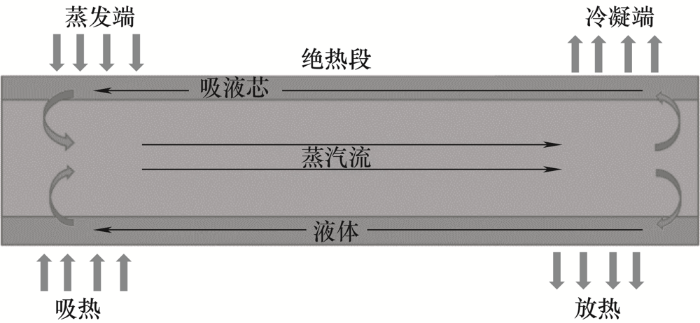

3.3 热管冷却系统

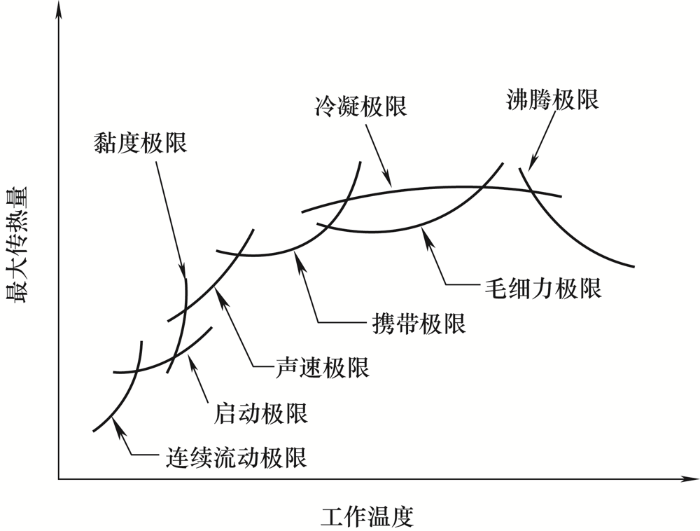

图16

式中,$\Delta {{P}_{c}}$为热管内部液体流动时的推动力;$\Delta {{P}_{v}}$为热管内蒸发端到冷凝端的蒸汽压降;$\Delta {{P}_{1}}$为冷凝端回到蒸发端的压降;$\Delta {{P}_{g}}$为由重力势能引起的流体压降,由热管环境所决定,数值可正可负[55]。

图17

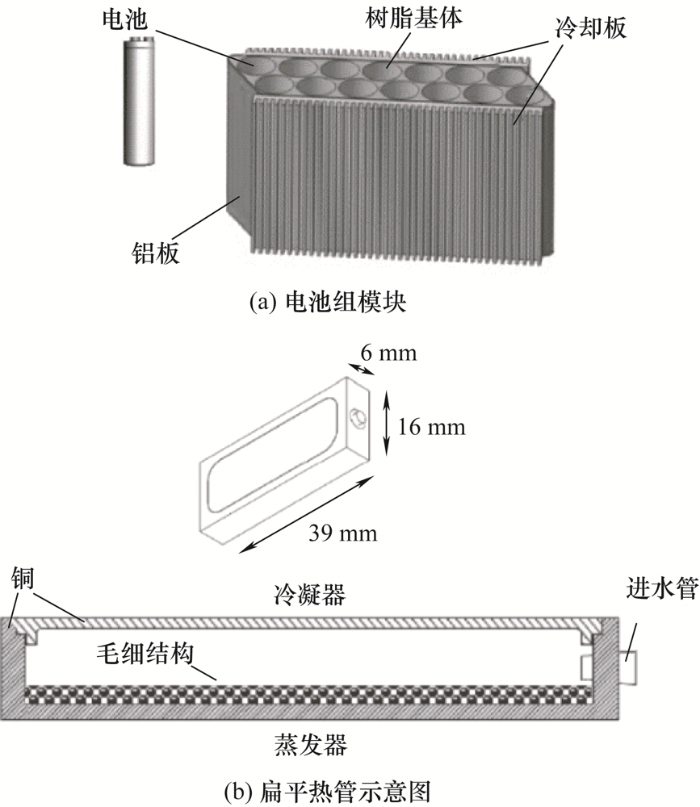

3.3.1 扁平热管

扁平热管(Flat heat pipe,FHP)与普通热管相比,可以更充分地接触电池表面,能够更快速、均匀地传递热量。

图18

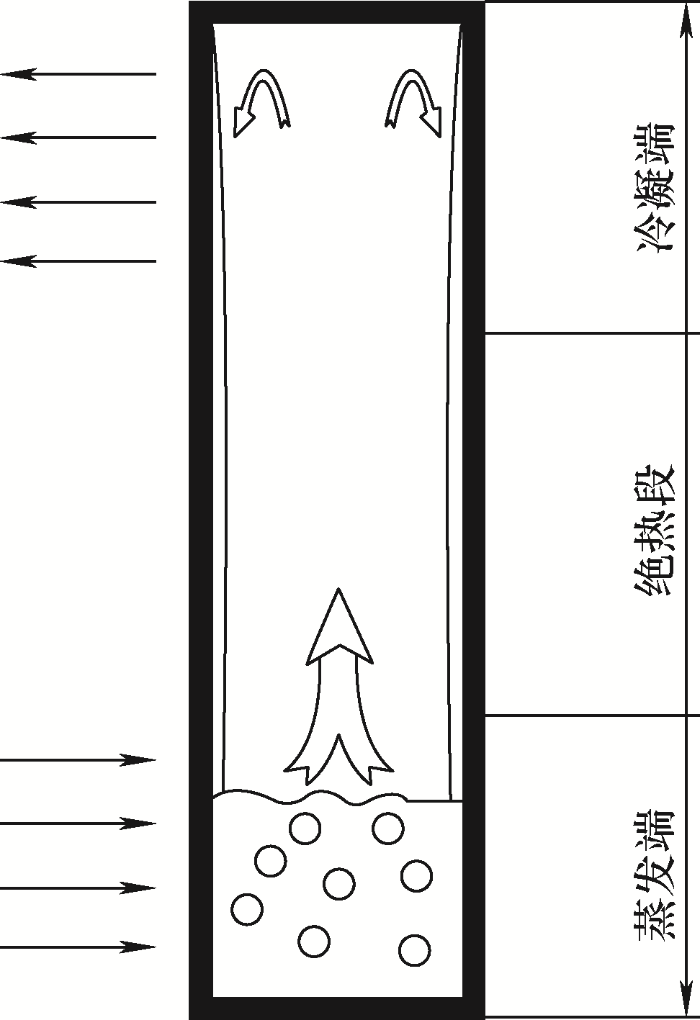

3.3.2 重力型热管

图19

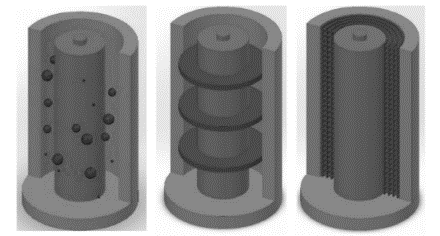

3.3.3 烧结热管

针对在微重力下热管内冷却液难回到蒸发端的问题,学者们采用了具有吸液芯结构的烧结热管。烧结热管能够在毛细力的作用下将冷却液从冷凝端送到蒸发端,同时吸液芯结构在循环中的速度更快,有利于热量的传递和扩散,提高了热管的传热效率。

近年来,烧结热管所遇到的问题为其结构和材料难以满足高热流密度环境下的散热,尤其在传热过程中由于真空腔厚度的增加导致局部烧干的情况。因此合理布置热管结构,选取适当的工质提高热管的传热率是今后的研究热点。

在进行基于扁平式烧结热管的方形电池散热试验中[60],研究了烧结热管对电池的散热特性和电池组的温度分布一致性。通过研究发现,在电池温升和局部温差的控制中,必须同时考虑热管的有效散热能力和均热能力;电池局部温差随热管倾斜角的减小而增大,当热管垂直安装时,电池局部温差受路面坡度影响较小,传热热阻可忽略不计;在周期性散热的工况下,扁平式烧结热管仍能保持良好的散热能力和热量均匀性。

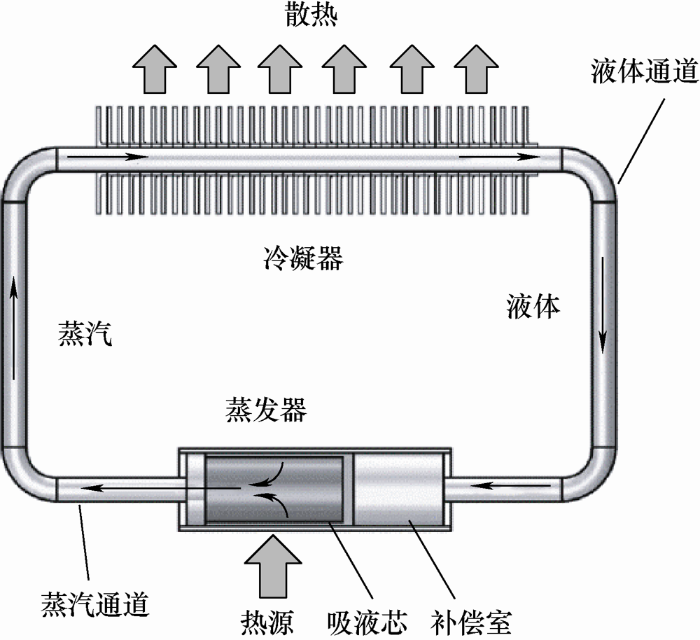

3.3.4 环路热管

图20

常见的环路热管有两种结构形式,分别为圆柱型和平板型。圆柱型的特点为蒸发受热均匀,且毛细芯能够得到充分的湿润。与圆柱型热管相比,平板型接触的电池面积更大,散热更加均匀,传热能力更为优秀。

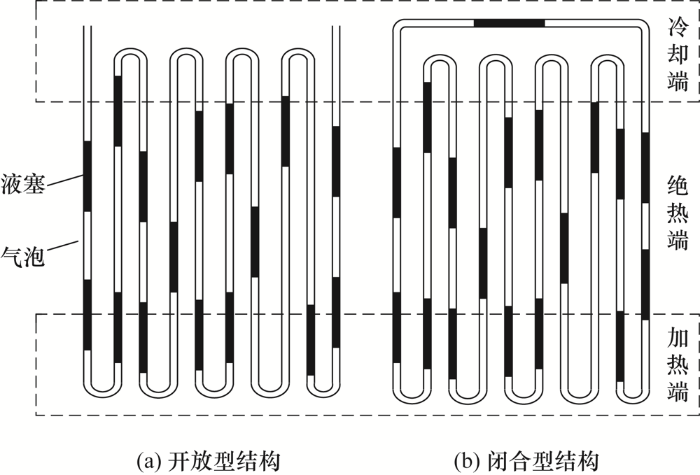

3.3.5 脉动热管

图21

与传统的热管相比,脉动热管具有体积小、结构简单、传热性能良好、适应性强、可对形状进行任意弯曲等优点。

综上分析,基于热管的电池热管理系统的显著优点为在不消耗任何功率的情况下降低最大温升,同时具有更高的导热性、安静无噪声、重量轻、结构灵活、轻维护和循环使用寿命长等优点。缺点为热管的容量小、接触面积小,对大型电池组需要使用更多的热管进行散热,以及无法对电池组进行加热。

3.4 相变材料冷却系统

相变材料(Phase change materials,PCM)的物理状态随温度而变化,相变过程中温度变化范围小,但吸收或释放的潜热大。相变材料具有体积变化小、潜热大、稳定性好等优点。

常见的PCM材料可分为有机材料、无机材料和共晶材料,有机材料包括石蜡(PA)和石蜡化合物,如硬脂酸和长链烷烃等;无机材料包括水合盐和金属等材料;共晶材料是两种或多种具有特定原子比的有机和无机化合物的混合,具有较高的潜热和较高的熔点[64]。

3.4.1 有机相变材料

常见的有机相变材料包括石蜡、脂肪酸、醇、酯、二酯和其他有机化合物。

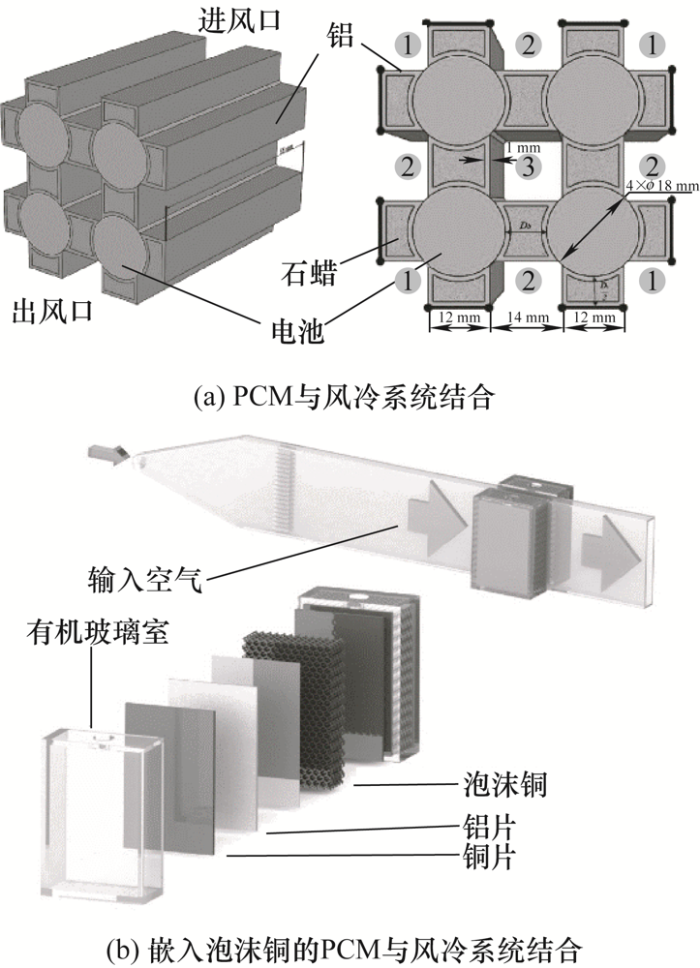

有机材料中由于石蜡具有高潜热、稳定性好、耐腐蚀和低成本的优点,被广泛应用于电池热管理系统中。由于易燃性和泄漏风险使得热管理系统中不会使用纯石蜡作为相变材料。针对这一问题,学者们提出一种有效方法,就是将膨胀石墨(EG)、金属泡沫铜、纳米流体和石墨毡等导热材料引入到纯有机相变材料中。

图22

试验结构表明,纳米颗粒的加入对电池散热特性影响很小,而翅片的添加使得电池温度显著下降,高导热性和三维结构的金属泡沫在降低电池温度方面相对最有效。

图23

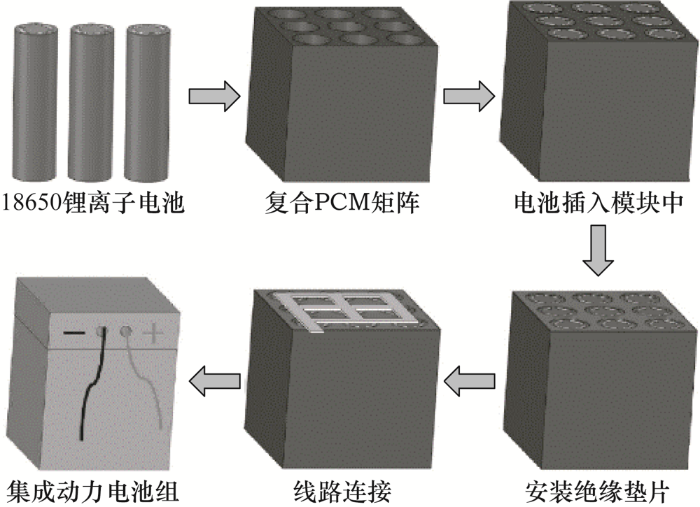

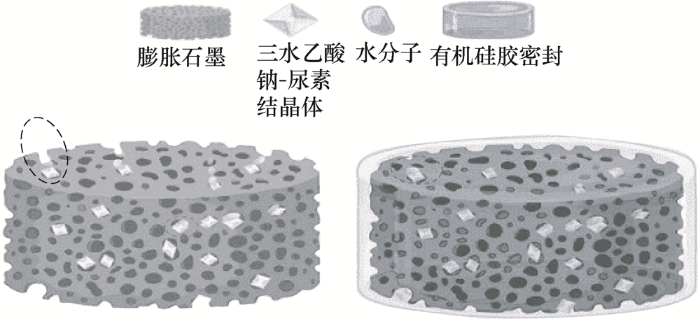

3.4.2 无机相变材料

图24

3.4.3 共晶材料

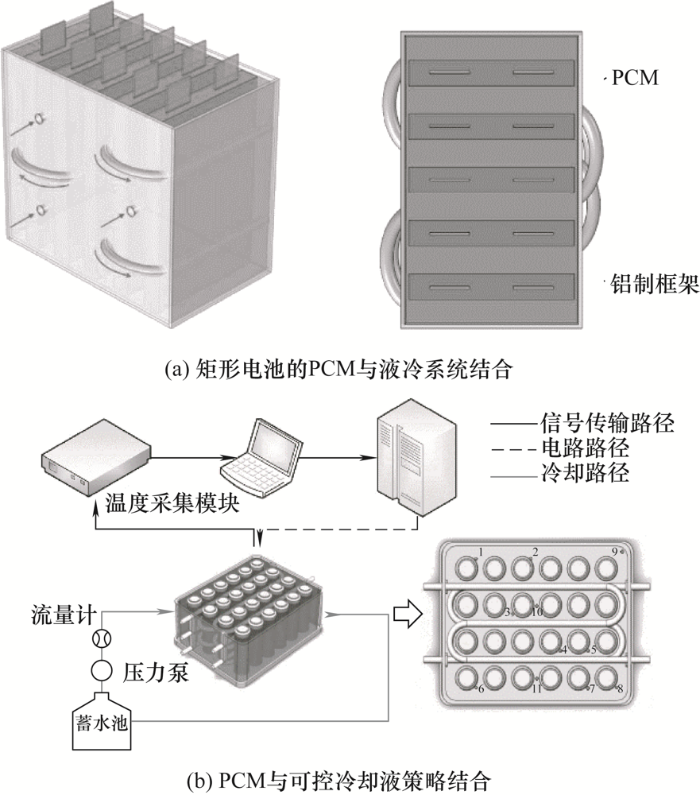

3.4.4 与PCM耦合冷却

表5 PCM耦合冷却系统综合比较

| 作者 | PCM材料 | 耦合冷却系统 | 电池材料 | 最大放电率 | 环境温度/℃ | 最大温升/℃ | 最大温差/℃ |

|---|---|---|---|---|---|---|---|

| HE等[71] | 石蜡/膨胀石墨/泡沫铜 | 风冷 | 钴酸锂电池 | 5C | 25 | 23.0 | 3.9 |

| HUANG等[72] | 石蜡/膨胀石墨 | 风冷 | 镍钴锰锂电池 | 3C | 25 | 33.24 | 4.74 |

| QIN等[70] | 石蜡/泡沫铝 | 风冷 | 18650锂电池 | 4C | 25 | 17 | 9.5 |

| HEKMAT等[73] | 聚乙二醇1000 | 液冷 | 锂电池 | 0.9C | 28 | 2 | 0.6 |

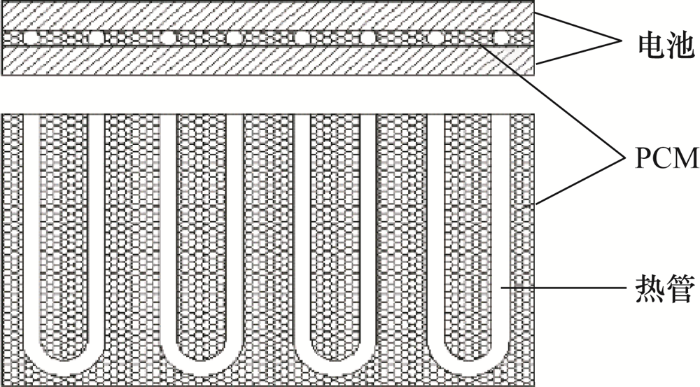

| KONG等[74] | 石蜡 | 液冷 | 镍钴锰锂电池 | 3C | 30 | 11.1 | 4 |

| PING等[75] | 膨胀石墨 | 液冷 | 磷酸铁锂电池 | 3C | 40 | 7.6 | 4.5 |

| ZHANG等[76] | 石蜡/泡沫铜 | 热管 | 磷酸铁锂电池 | 5C | 30 | 18.8 | 4 |

| JIANG等[77] | 石蜡/膨胀石墨 | 热管 | 磷酸铁锂电池 | 1.92C | 40 | 7.9 | 2.6 |

| WANG等[78] | 石蜡 | 热管 | — | 30 W | 25 | 20.56 | — |

图25

图26

图27

4 总结与展望

储能电池作为电动汽车的核心,散热问题是电池热管理系统的关键技术之一。基于电池散热的研究现状和研究趋势,未来的热管理系统可从以下方面展开。

(1) 风冷方式的散热结构简单,设计轻巧便捷,但冷却效率较低,很多情况不适于电动汽车的电池散热。气流通道和电池排布的优化是未来的研究方向。

(2) 相比于风冷,液冷具有更高的散热效率,能使电池组温度保持在正常温度范围内,且使单体电池呈现出更好的温度均匀性。由于需要额外的冷却剂循环器件,增加了电路的复杂性、整车的重量与能耗,且有漏液的风险。通道形状和数量优化是重点研究方向。纳米流体作为冷却剂的性能还需要进一步研究。

(3) 热管作为一种导热工具,具有更高的导热率,但由于蒸发器和冷凝器部分的接触面积小和体积较大等原因,在实际应用中难以集成。额外能源消耗的削减和系统结构的简化是未来的发展趋势。

(4) 大多数的PCM导热系数较低,直接影响到电池的散热效率。因此寻找高导热率的PCM一直是研究重点。如果在连续的高倍率充放电循环中仅使用PCM来控制电池温度,可能无法达到理想的效果。因此,需要额外的冷却系统来进行辅助,以协助散热。PCM与其他冷却系统的结合是电池热管理系统的发展趋势之一。

目前PCM材料正慢慢向直冷靠近,相变材料使用制冷剂R134a。通过制冷剂的相变过程将热量带走。典型的例子有BWM i3,散热效果比液冷高出3~4倍,且避免了乙二醇液体在电池内部流动造成的氧化腐蚀。当然制冷方式只能进行散热,需要安装加热器来进行加热。

未来对高功率、高能量密度和高充电效率电池的需求将持续增长,随之而来的是对更高效、更稳定、更经济、更紧凑的电池热管理系统的需求。从低能耗和结构角度来看,PCM的散热系统更具有潜力,需要进一步研究来提高商业应用性。首先,寻找高导热率的PCM来代替;其次,设计以PCM为主体,其他散热系统为辅助的协同机制,以保证电池热管理系统的耐久性。

参考文献

计及碳排放的输电网侧“风-车协调”研究

[J].

Research on “wind-vehicle coordination” on the transmission grid side considering carbon emissions

[J].

纯电动汽车的应用及发展概述

[J].

An overview of the application and development of pure electric vehicles

[J].

Memory effect in a lithium-ion battery

[J].

DOI:10.1038/nmat3623

PMID:23584142

[本文引用: 1]

Memory effects are well known to users of nickel-cadmium and nickel-metal-hydride batteries. If these batteries are recharged repeatedly after being only partially discharged, they gradually lose usable capacity owing to a reduced working voltage. Lithium-ion batteries, in contrast, are considered to have no memory effect. Here we report a memory effect in LiFePO4-one of the materials used for the positive electrode in Li-ion batteries-that appears already after only one cycle of partial charge and discharge. We characterize this memory effect of LiFePO4 and explain its connection to the particle-by-particle charge/discharge model. This effect is important for most battery uses, as the slight voltage change it causes can lead to substantial miscalculations in estimating the state of charge of batteries.

Challenges in the development of advanced Li-ion batteries:A review

[J].

串联锂离子电池组均衡拓扑综述

[J].

A review of the equilibrium topology of lithium-ion battery packs in series

[J].

The low temperature performance of Li-ion batteries

[J].DOI:10.1016/S0378-7753(02)00618-3 URL [本文引用: 1]

Battery thermal management in EVs and HEVs:Issues and solutions

[J].

Capacity fade of Sony 18650 cells cycled at elevated temperatures Part II. Capacity fade analysis

[J].DOI:10.1016/S0378-7753(02)00473-1 URL [本文引用: 3]

A critical review of thermal issues in lithium-ion batteries

[J].DOI:10.1149/1.3515880 URL [本文引用: 2]

Online estimation of capacity fade and power fade of lithium-ion batteries based on input-output response technique

[J].DOI:10.1109/TTE.2017.2775801 URL [本文引用: 1]

Cycling degradation of an automotive LiFePO4lithium-ion battery

[J].

Aging mechanisms of LiFePO4 batteries deduced by electrochemical and structural analyses

[J].DOI:10.1149/1.3294790 URL [本文引用: 2]

Lithium-ion battery aging experiments at subzero temperatures and model development for capacity fade estimation

[J].DOI:10.1109/TVT.2015.2473841 URL [本文引用: 2]

Influence of charge rate on the cycling degradation of LiFePO4/mesocarbon microbead batteries under low temperature

[J].DOI:10.1007/s11581-017-2032-y URL [本文引用: 2]

A critical review of battery thermal performance and liquid based battery thermal management

[J].

DOI:10.1016/j.enconman.2018.12.051

[本文引用: 1]

Electric vehicles with green power system are viable alternatives to reduce greenhouse gas emissions and dependence on fossil energy resources. The power source such as Li-ion battery has high sensitivity to temperature, which is a challenge related to battery thermal management. Battery thermal management system plays a vital role in the high efficiency, dependability and security of these batteries. Modern commercial electric vehicles normally use liquid based battery thermal management system, which has high heat transfer efficiency with the function of cooling or heating. This paper firstly looks at the effects of temperature on the battery performance from three aspects: low temperature, high temperature and differential temperature. Then the battery management system is discussed with the main emphasis on battery modeling methods and thermal management strategies. Further, a systematic review of liquid based system is presented in terms of direct and indirect contact mode. Progress made in liquid channel configuration and heat transfer fluid aiming at improving the overall thermal performance is also discussed. With the function of liquid-gas phase change process, the heat pipe based battery thermal management is feasible and effective for its high heat transfer efficiency. To further facilitate vehicle-mounted energy optimization, an integrated vehicle thermal management system with appropriate energy allocation is required. In addition, the battery thermal management system connected with the other subsystems (e.g., heating ventilation air conditioning system) by utilizing the liquid circulation in vehicle thermal management has great potential in energy-saving and efficiency promotion.

Battery thermal management system

[C]//

Review on battery thermal management system for electric vehicles

[J].

DOI:10.1016/j.applthermaleng.2018.12.020

[本文引用: 1]

The lithium-ion batteries are widely used for electric vehicles due to high energy density and long cycle life. Since the performance and life of lithium-ion batteries are very sensitive to temperature, it is important to maintain the proper temperature range. In this context, an effective battery thermal management system solution is discussed in this paper. This paper reviews the heat generation phenomena and critical thermal issues of lithium-ion batteries. Then various battery thermal management system studies are comprehensively reviewed and categorized according to thermal cycle options. The battery thermal management system with a vapor compression cycle includes cabin air cooling, second-loop liquid cooling and direct refrigerant two-phase cooling. The battery thermal management system without vapor compression cycle includes phase change material cooling, heat pipe cooling and thermoelectric element cooling. Each battery thermal management system is reviewed in terms of the maximum temperature and maximum temperature difference of the batteries and an effective BTMS that complements the disadvantages of each system is discussed. Lastly, a novel battery thermal management system is proposed to provide an effective thermal management solution for the high energy density lithium-ion batteries.

A comprehensive review on thermal management systems for power lithium-ion batteries

[J].DOI:10.1016/j.rser.2020.110685 URL [本文引用: 1]

Investigation of thermal management system of a lithium-ion battery in electric vehicle

[J].

A review on battery thermal management in electric vehicle application

[J].DOI:10.1016/j.jpowsour.2017.09.046 URL [本文引用: 1]

相变材料和液冷耦合散热的锂电池热管理研究

[J].

Thermal management of lithium battery with phase change material and liquid-cooling coupling heat dissipation

[J].

Integrated electro-thermal model for pouch lithium ion batteries

[J].DOI:10.1016/j.matcom.2020.03.010 URL [本文引用: 1]

Battery thermal management system design modeling

[R].

A pseudo three-dimensional electrochemical-thermal model of a cylindrical LiFePO4/graphite battery

[J].DOI:10.1016/j.applthermaleng.2018.10.108 URL [本文引用: 1]

Lithium-ion battery overcharging thermal characteristics analysis and an impedance-based electro-thermal coupled model simulation

[J].

Thermal-electrochemical simulation of electrochemical characteristics and temperature difference for a battery module under two-stage fast charging

[J].DOI:10.1016/j.est.2020.101307 URL [本文引用: 1]

Comprehensive electro-thermal model of 26650 lithium battery for discharge cycle under parametric and temperature variations

[J].DOI:10.1016/j.est.2020.101222 URL [本文引用: 1]

An improved resistance-based thermal model for prismatic lithium-ion battery charging

[J].DOI:10.1016/j.applthermaleng.2020.115794 URL [本文引用: 1]

Battery performance models in ADVISOR

[J].DOI:10.1016/S0378-7753(02)00194-5 URL [本文引用: 1]

Three-dimensional thermal abuse model for lithium-ion cells

[J].DOI:10.1016/j.jpowsour.2007.04.018 URL [本文引用: 1]

混合动力汽车动力电池组散热特性实验研究

[J].

Experimental research on heat dissipation characteristics of hybrid electric vehicle power battery pack

[J].

Experimental study on the thermal management performance of air cooling for high energy density cylindrical lithium-ion batteries

[J].

DOI:10.1016/j.applthermaleng.2019.03.157

[本文引用: 2]

To comprehensively investigate the characteristics of an air cooling system, a battery pack with 32 high energy density cylindrical lithium-ion batteries is designed in this paper. Using a series of evaluation parameters, the air cooling performances of aligned, staggered, and cross battery packs are experimentally studied and compared at different air inlet velocities. Additionally, the cooling effect and capacity of the air cooling system are investigated by changing the discharge rate and air inlet temperature. Finally, the energy efficiency of the air cooling system under various operating conditions is studied. It is found that the aligned arrangement has the best cooling performance and temperature uniformity, followed by the staggered and finally the cross arrangement. The minimum temperature always occurs in the second column along the direction of the air inlet. The parasitic power consumption increases exponentially with the air inlet velocity, and the aligned arrangement has the lowest power consumption, up to 23% less than that of the cross arrangement. Additionally, the energy efficiency of the air cooling system decreases with the increasing air velocity, and the cooling capacity has an upper limit that is proportional to the discharge rate.

Combined experimental and numerical study of thermal management of battery module consisting of multiple Li-ion cells

[J].DOI:10.1016/j.ijheatmasstransfer.2014.01.038 URL [本文引用: 2]

Cooling efficiency improvement of air-cooled battery thermal management system through designing the flow pattern

[J].DOI:10.1016/j.energy.2018.11.011 URL [本文引用: 2]

Battery thermal management in EVs and HEVs:Issues and solutions

[C]//

Boiling liquid battery cooling for electric vehicle

[C]//

Battery thermal management by boiling heat-transfer

[J].

Investigation of power battery thermal management by using mini-channel cold plate

[J].DOI:10.1016/j.enconman.2014.10.015 URL [本文引用: 2]

Influence of operating conditions on the optimum design of electric vehicle battery cooling plates

[J].DOI:10.1016/j.jpowsour.2013.06.114 URL [本文引用: 2]

Ultra-thin minichannel LCP for EV battery thermal management

[J].DOI:10.1016/j.apenergy.2013.07.013 URL [本文引用: 1]

Numerical investigation on thermal characteristics of a liquid-cooled lithium-ion battery pack with cylindrical cell casings and a square duct

[J].DOI:10.1016/j.est.2022.104041 URL [本文引用: 2]

Performance analysis on liquid-cooled battery thermal management for electric vehicles based on machine learning

[J].DOI:10.1016/j.jpowsour.2021.229727 URL [本文引用: 1]

Energy consumption of battery cooling in hybrid electric vehicles

[C]//

Coupled prediction model of liquid-cooling based thermal management system for cylindrical lithium-ion module

[J].DOI:10.1016/j.applthermaleng.2020.115599 URL [本文引用: 1]

Simulation study of lithium-ion battery thermal management system based on a variable flow velocity method with liquid metal

[J].DOI:10.1016/j.applthermaleng.2020.115578 URL [本文引用: 1]

动力电池热管冷却效果实验

[J].

Experiment on cooling effect of power battery heat pipe

[J].

Heat pipe-based waste heat recovery systems:Background and applications

[J].DOI:10.1016/j.tsep.2022.101221 URL [本文引用: 1]

新型双向阀门可控热导热管研究

[J].

Research on a new type of two-way valve controllable thermal heat pipe

[J].

热管技术及其应用

[J].

Heat pipe technology and its application

[J].

热管技术的原理应用与发展

[C]//

The principle application and development of heat pipe technology

[C]//

Experimental investigation on the feasibility of heat pipe cooling for HEV/EV lithium-ion battery

[J].DOI:10.1016/j.applthermaleng.2013.11.048 URL [本文引用: 1]

Loop heat pipes

[J].DOI:10.1016/j.applthermaleng.2004.07.010 URL [本文引用: 1]

超薄微热管的研究现状及发展趋势

[J].

DOI:10.3901/JME.2017.20.131

[本文引用: 1]

快速增加的系统发热已经成为当代先进微电子芯片系统研发和应用中的一项重大技术挑战。热管以其高导热率、高冷却能力、高稳定性和长寿命等优点在高热流密度元件的散热技术领域得到广泛应用。但是,随着电子产品不断朝着高性能化与轻薄化的方向发展,传统圆柱型微热管或普通压扁型热管已难以应用于紧凑、轻薄型的电子设备散热,体积更小、质量更轻、厚度更薄的超薄微热管已成为目前热管技术的重要发展方向和研究热点。详细介绍了超薄微热管的类型及应用,重点综述了目前国内外关于超薄微热管在成形工艺及吸液芯结构等方面的研究进展情况,分析讨论了其在电子器件散热中的发展所存在的问题,并进行科学预测与展望。

Research status and development trend of ultra-thin micro heat pipes

[J].

DOI:10.3901/JME.2017.20.131

[本文引用: 1]

The rapid increase of heat generation level has become a major technical challenge in the development and applications of contemporary advanced microelectronic chip system. As an efficient heat transfer device, micro heat pipes have been widely used for thermal management of electronic devices because of their excellent thermal performance and high reliability. However, with electronic devices becoming highly integrated, lighter, and thinner, traditional micro heat pipes cannot meet the usage requirement. An ultra-thin micro heat pipe has been proposed and has become the research focus of modern heat pipe technology. The types and applications of ultra-thin micro heat pipe are introduced, as well as the research progresses of wick structure and forming process of ultra-thin micro heat pipe are summarized. Furthermore, the problems existed on ultra-thin micro heat pipe technology are pointed out and it is also suggested that more efforts should be made to what in the future.

脉动热管技术研究进展

[J].

Research progress of pulsating heat pipe technology

[J].

Phase-change materials (PCM) for automotive applications:A review

[J].

Battery thermal management with thermal energy storage composites of PCM,metal foam,fin and nanoparticle

[J].DOI:10.1016/j.est.2020.101235 URL [本文引用: 1]

Experimental investigation of the flame retardant and form-stable composite phase change materials for a power battery thermal management system

[J].

Battery thermal management based on multiscale encapsulated inorganic phase change material of high stability

[J].DOI:10.1016/j.applthermaleng.2021.117002 URL [本文引用: 1]

Design of eutectic hydrated salt composite phase change material with cement for thermal energy regulation of buildings

[J].DOI:10.3390/ma14010139 URL [本文引用: 1]

六水硝酸镁-硝酸锂共晶盐/膨胀石墨复合相变材料的制备及性能强化

[J].

Preparation and performance enhancement of magnesium nitrate hexahydrate-lithium nitrate eutectic salt/expanded graphite composite phase change material

[J].

Experimental and numerical study on a novel hybrid battery thermal management system integrated forced-air convection and phase change material

[J].

A phase change material with enhanced thermal conductivity and secondary heat dissipation capability by introducing a binary thermal conductive skeleton for battery thermal management

[J].

DOI:10.1016/j.applthermaleng.2018.11.100

[本文引用: 1]

In order to enhance the thermal conductivity and secondary heat dissipation capability of the phase change material (PCM) in battery thermal management (BTM) applications, a new kind of composite PCM (CPCM) is successfully prepared by constructing a binary thermal conductive skeleton of expanded graphite (EG)/copper foam (CF). The EG with porous structure can adsorb the PCM of paraffin and act as a micro-thermal-conductive framework to transfer the heat to the adjacent CF skeleton. The CF acts as a macro-skeleton to transfer the heat throughout the CPCM plate and enhance the heat transfer coefficient of the interface between the CPCM plate and air. In consequence, the obtained CPCM-based battery pack with EG/CF (CPCM-EG/CF) delivers much better cooling and temperature-uniformed performances than those without EG/CF or CF, especially under a secondary heat dissipation system of forced air convection. For example, the CPCM-EG/CF pack shows stable and lowest maximum temperature and temperature difference of 48.0 and 3.9 degrees C during the cycling charge-discharge tests under forced air flow, respectively.

High-dimensional model representation-based global sensitivity analysis and the design of a novel thermal management system for lithium-ion batteries

[J].

DOI:10.1016/j.enconman.2019.04.013

[本文引用: 1]

Thermal management is indispensable to the lithium-ion battery packs utilized in electrical vehicles. In this study, a novel air-cooling-based battery thermal management system with the heat fins-assisted phase change material/expanded graphite structure is proposed. After verification of the accuracy of the thermal model based on experimental measurements, numerical studies are performed on a battery submodule. All the results are obtained at an ambient temperature of 25 degrees C. Considering the complexity of the multi-physics modeling, a Kriging-based high-dimensional model representation method is employed to perform the global sensitivity analysis with relatively low computational effort. The results reveal the influence of the design variables on the thermal performance of the proposed cooling system. Moreover, this method reveals the correlations between the design variables, which reduce the dimensions of the given problem and improve the computational efficiency during optimization. Finally, a series of simulation-based tests is performed to validate the superiority of the optimal cooling system under realistic and extreme operation conditions. The comparison results show that this system can effectively improve the thermal behavior of the battery, and this cooling system after optimization provides much better cooling efficiency in alleviating the temperature increase and reducing the temperature difference of the batteries within the battery packs compared to the original one.

Hybrid thermal management of a Li-ion battery module with phase change material and cooling water pipes:An experimental investigation

[J].DOI:10.1016/j.applthermaleng.2019.114759 URL [本文引用: 1]

A novel battery thermal management system coupling with PCM and optimized controllable liquid cooling for different ambient temperatures

[J].

Investigation on battery thermal management system combining phase changed material and liquid cooling consid- ering non-uniform heat generation of battery

[J].

A novel heat pipe assisted separation type battery thermal management system based on phase change material

[J].DOI:10.1016/j.applthermaleng.2019.114571 URL [本文引用: 1]

Lithium-ion battery thermal management using heat pipe and phase change material during discharge-charge cycle:A comprehensive numerical study

[J].DOI:10.1016/j.apenergy.2019.03.043 URL [本文引用: 1]

Thermal performance of phase change material/oscillating heat pipe-based battery thermal management system

[J].DOI:10.1016/j.ijthermalsci.2015.11.005 URL [本文引用: 1]

Thermal issues about Li-ion batteries and recent progress in battery thermal management systems:A review

[J].DOI:10.1016/j.enconman.2017.08.016 URL [本文引用: 1]