1 引言

塑料是以合成树脂为主要原料的工业制品,广泛应用于工业、农业、生活和国防军工等领域。最近几年,国家出台了一系列经济刺激的计划,国内工业快速增长的同时,也拉动了塑料制品的需求。注塑机是塑料行业的主要生产和能耗设备,按照动力系统分类,注塑机可以分为液压和全电动两种,目前国内全电动注塑机的技术还不成熟,现存的传统注塑机主要是采用定量泵和比例流量、压力复合阀的液压控制系统,但是采用定量泵存在大量的节流和溢流损失[1],有较大的节能改造空间。太原理工大学在注塑机上进行不同泵与电机的组合研究,结果表明永磁同步电动机驱动定量泵的伺服控制系统存在巨大的节能潜力[2,3],这种方式也便于注塑机动力系统的节能改造。相比传统异步电动机,永磁同步电动机具有诸多优势,高校、科研院所以及企业对注塑机用永磁同步电动机进行了相关的研究。

近年来,随着电机制造企业对注塑行业的深入了解和永磁伺服电动机的研究与开发,注塑机用永磁伺服电动机各项性能稳定性逐渐提高,返修率得到很大的降低,主要解决了电机齿槽转矩大、电机温升过高退磁、轴承发热及电磁线损坏等问题。高校方面,沈阳工业大学黄忠诚采用72槽8极的组合设计了一款低速大扭矩永磁同步电动机,通过三维有限元软件对电动机进行热分析,并采用定子水冷的方式合理控制了电动机的运行温度,抑制了低速运行时的转矩脉动,保证了注射成型的工艺精度[4]。广东工业大学刘景辉对不同槽极组合的永磁同步电动机进行径向力波分析,最终确定48槽8极的槽极组合,采用不均匀气隙和优化极弧系数的方法,设计一款低噪声注塑机用永磁同步电动机[5],但是48槽8极的齿槽转矩较大,采用定子斜槽工艺难度较大,生产制造成本较高。广东工业大学赖文海设计一款52kW,48槽8极注塑机用永磁同步电动机,通过一种磁极偏移方法降低了电动机的齿槽转矩,但是磁极偏移造成转子磁场谐波含量增加[6],使得电动机的杂散损耗和电磁噪声变大。

本文利用Ansys Maxwell 2D软件仿真分析设计一款11.8kW、1 500r/min注塑机用永磁同步电动机,侧重对槽极组合、转子结构进行分析与设计,使其达到优化齿槽转矩、改善动态性能和减小噪声的目的。该永磁同步电动机用于注塑机伺服系统改造,通过分析实验数据,验证了电动机设计的可靠性,并取得较好的节能效果。

2 主要尺寸确定

本文设计一款永磁同步电动机,用于注塑机伺服节能改造。电动机有较小的转动惯量和较低的噪声,其主要技术指标见表1。

表1 主要技术指标

Tab.1

| 参 数 | 数 值 | 参 数 | 数 值 | |

|---|---|---|---|---|

| 额定功率/kW | 11.8 | 额定转速/(r/min) | 1 500 | |

| 最大转速/(r/min) | 2 000 | 额定转矩/N·m | 75 | |

| 过载倍数 | 2以上 | 效率(%) | 91.2以上 |

结合注塑机用永磁伺服电动机外形安装尺寸的行业标准,以及便于有传统电机制造基础的企业生产,定子外圆D1取值175mm,内圆Dli取值110mm。目前,永磁伺服电动机均采用牌号较高的稀土钕铁硼磁钢,为降低气隙磁场的谐波含量、杂散损耗以及电动机振动和噪声,永磁同步电动机的气隙一般大于同规格异步电动机,为保证电动机具有一定的弱磁扩速能力,气隙不宜取得较大,本设计取单边最小气隙为1.1mm。

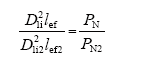

注塑机的生产过程是周期性工作制,单位生产周期包括合模、锁模、射胶、保压、溶胶、冷却和开模等工艺过程,各动作执行所需要的压力和转速不同,注塑机单位生产周期的所需平均功率占电动机额定功率的60%~80%,取电动机的额定负载绕组温升为65K,热负荷A·J≤450A2/m3,磁负荷Bδavg选取0.6~0.65T,铁心长度lef的确定通常参考相似的电机尺寸,根据以下公式计算[7]

式中,Dli2为参考电机的定子内圆;lef2为参考电机的铁心长度;PN2为参考电机的额定功率。通过计算,确定铁心长度lef为140mm。

3 槽极组合选择

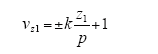

目前注塑机用永磁伺服电动机产品的槽极组合主要采用48槽8极、36槽8极和36槽12极。

式中,k为齿谐波次数,k = 1, 2, 3, …;z1为定子槽数;p为极对数。由于36槽12极的极数较多,齿谐波频谱分布密集,同时整数槽的齿槽转矩较大,但是极距τ = 3槽,绕组端部较短,铜耗较小,有效导体所占比例较大,有利于提高电机的过载倍数,多用于高功率密度、低速大力矩等场合[8]。

36槽8极的定子谐波磁场含量比48槽8极略高,但齿槽转矩较小,不用磁极偏移。另一方面,36槽8极端部较短,还可以采用单双层绕组进一步缩短端部长度。36槽8极组合综合了36槽12极和48槽8极的优点,综合考虑注塑机的生产要求,本文采用36槽8极的组合。

4 转子结构设计

4.1 转子结构选择

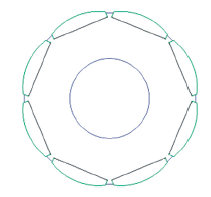

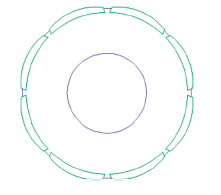

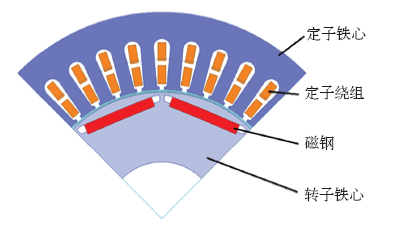

图1

图2

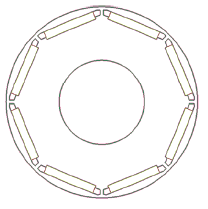

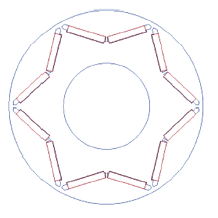

内置式的转子结构极间和端部漏磁较大,但是可以通过合理设置隔磁桥、适当减小气隙和加长转子铁心等方法来减小漏磁的影响。内置式转子结构的磁钢制作工艺最简单,且其等效气隙较小,弱磁能力较强,另一方面,内置式转子结构的凸极率较大,能够提供较大的磁阻转矩,有利于提高电机的过载倍数。图3和图4为常用的内置式转子结构,除了这两种磁钢形式外,还有“U”形、“W”形等形式。“一”形磁钢适用于转速较低,有足够转子空间的情况,“V”、“U”和“W”形磁钢结构适合转速较高、转子空间有限及高功率密度等情况。注塑机用永磁伺服电动机要求有较好的动态性能,在转子铁心上钻孔能减小电机的转动惯量,采用“一”形磁钢可以有足够的空间钻孔,本设计采用“一”形磁钢内置式的转子结构[9]。

图3

图4

4.2 转子结构尺寸确定

永磁电机与传统电机存在许多不同之处,其中齿槽转矩是永磁电机的固有问题,也是永磁电机设计过程中不可忽略的问题。永磁电机大部分转子结构尺寸通常以削弱齿槽转矩为目的来确定,特别是在低速运行稳定性和控制精度要求较高的领域。

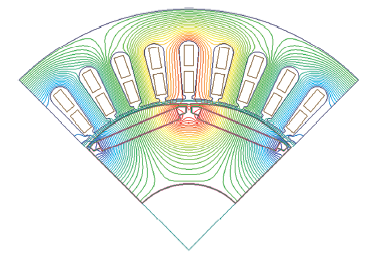

表贴式转子结构永磁电机通常采用不均匀气隙、优化极弧系数和磁极偏移的组合方式,达到削弱齿槽转矩的目的。内置式永磁电机的齿槽转矩削弱的方法与表贴式结构类似,只是内置式转子结构较为复杂,难以构建数学模型,无法通过解析计算确定转子的结构尺寸。本文采用Ansys Maxwell 2D搭建内置式永磁电机的二维有限元模型,采用不均匀气隙和优化极弧系数的组合方式来削弱齿槽转矩。

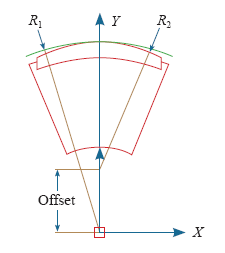

4.2.1 不均匀气隙优化

图5

图6

图7

图8

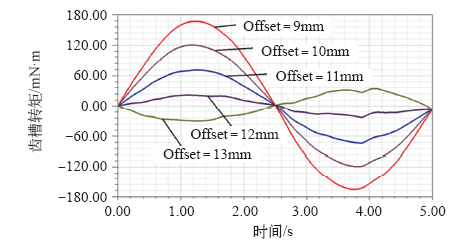

计算不同偏心距下转子的气隙磁场强度和及其谐波畸变率见表2。

表2 气隙磁场强度和谐波畸变率

Tab.2

| Offset/mm | Bδavg /T | 谐波畸变率(%) |

|---|---|---|

| 9 | 0.675 2 | 19.90 |

| 10 | 0.664 4 | 17.96 |

| 11 | 0.656 0 | 17.26 |

| 12 | 0.644 8 | 16.23 |

| 13 | 0.635 9 | 15.68 |

随着偏心距的增大,谐波畸变率降低趋势逐渐趋缓,并且在偏心距为12mm时齿槽转矩最小,本设计取偏心距为12mm。

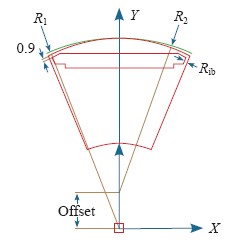

4.2.2 极弧系数优化

图9

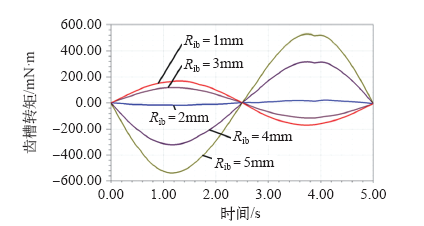

取Offset = 12mm,对不同Rib值进行参数化扫描,计算得到低转速下的齿槽转矩如图10所示。

图10

由图10可以看出Offset = 12mm,Rib = 2mm时的齿槽转矩最小,齿槽转矩为5.6N·m,通过不均匀气隙和极弧系数的组合优化,可以有效削弱“一”型磁钢内置式转子结构的齿槽转矩。

4.2.3 转子铁心钻孔

图11

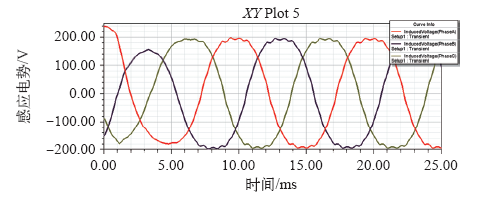

对转子结构进行优化后,通过仿真分析得到反电动势波形如图12所示。可以看出,波形正弦度较好。

图12

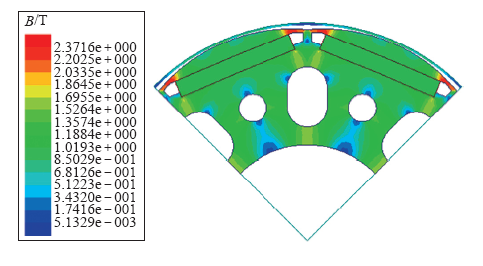

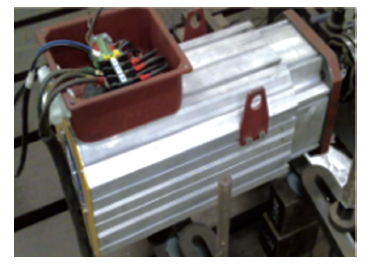

5 样机制作与实验

图13

表3 设计值与实验值对比

Tab.3

| 对比参数 | 设计值 | 实验值 | 误差(%) |

|---|---|---|---|

| 额定电压/V | 326 | 321 | 1.5 |

| 额定电流/A | 22.3 | 22.8 | 2.2 |

| 额定转矩/N·m | 75 | 75 | 0 |

| 效率(%) | 92.2 | 91.6 | 0.6 |

| 额定绕组温升/K | – | 61 | – |

| 过载倍数 | 2.3 | 2.15 | 6.5 |

| 额定噪声/dB | – | 63 | – |

本次设计的样机用于注塑机节能改造,与原来工频异步电机的电流和能耗对比见表4,改用永磁伺服系统的可以取得较好节能效果。

表4 伺服节能改造数据对比

Tab.4

| 成型工艺 | 工频异步电机 | 永磁同步电机 |

|---|---|---|

| 射胶电流/A | 18.4 | 12.5 |

| 保压电流/A | 14.5 | 6.7 |

| 溶胶电流/A | 20.0 | 13.7 |

| 冷却电流/A | 6.3 | 0 |

| 开模电流/A | 12.5 | 8.6 |

| 顶针电流/A | 14.5 | 5.1 |

| 待机电流/A | 6.3 | 0 |

| 节电率(%) | 48 | |

6 结论

本文针对注塑机生产过程的特点和要求,设计一款与之要求相符的永磁同步电动机。文中侧重对电机的槽极组合选择和转子结构进行分析与设计,采用不均匀气隙、优化极弧系数来削弱齿槽转矩,通过转子钻孔降低转动惯量,提高电机的的动态性能。根据设计参数制作样机,并用于纯液压注塑机伺服节能改造,通过分析发现能取得明显的节能效果。

参考文献

泵控缸电液技术研究现状、存在问题及创新解决方案

[J].

Research status, existing problems and innovative solutions of pump-controlled electrohydraulic technology

[J].

伺服电动机定量液压泵驱动的注塑机电液控制系统分析

[J].

DOI:10.1126/sciadv.aax5746

URL

PMID:31646178

[本文引用: 1]

Soft tubular actuators can be widely found both in nature and in engineering applications. The benefits of tubular actuators include (i) multiple actuation modes such as contraction, bending, and expansion; (ii) facile fabrication from a planar sheet; and (iii) a large interior space for accommodating additional components or for transporting fluids. Most recently developed soft tubular actuators are driven by pneumatics, hydraulics, or tendons. Each of these actuation modes has limitations including complex fabrication, integration, and nonuniform strain. Here, we design and construct soft tubular actuators using an emerging artificial muscle material that can be easily patterned with programmable strain: liquid crystal elastomer. Controlled by an externally applied electrical potential, the tubular actuator can exhibit multidirectional bending as well as large (~40%) homogenous contraction. Using multiple tubular actuators, we build a multifunctional soft gripper and an untethered soft robot.

Analysis of injection molded electro-hydraulic control system driven by quantitative hydraulic pump of servo motor

[J].

DOI:10.1126/sciadv.aax5746

URL

PMID:31646178

[本文引用: 1]

Soft tubular actuators can be widely found both in nature and in engineering applications. The benefits of tubular actuators include (i) multiple actuation modes such as contraction, bending, and expansion; (ii) facile fabrication from a planar sheet; and (iii) a large interior space for accommodating additional components or for transporting fluids. Most recently developed soft tubular actuators are driven by pneumatics, hydraulics, or tendons. Each of these actuation modes has limitations including complex fabrication, integration, and nonuniform strain. Here, we design and construct soft tubular actuators using an emerging artificial muscle material that can be easily patterned with programmable strain: liquid crystal elastomer. Controlled by an externally applied electrical potential, the tubular actuator can exhibit multidirectional bending as well as large (~40%) homogenous contraction. Using multiple tubular actuators, we build a multifunctional soft gripper and an untethered soft robot.

基于Maxwell的整数槽永磁同步电动机分析与设计

[J].

DOI:10.4142/jvs.2019.20.e73

URL

PMID:31775199

[本文引用: 3]

Chronic kidney disease is considered to be most common in geriatric domestic cats. It has been reported that the feline viral rhinotracheitis, calicivirus, and panleukopenia (FVRCP) vaccine prepared from the Crandell-Rees feline kidney (CRFK) cell line can induce cross-reactions of antibodies with feline kidney tissues. As an anti-cat kidney antibody was not available commercially for this study of autoantibody in cats, the purpose of this study was to produce anti-cat kidney antibody in rabbits for further study of autoantibody in cats after FVRCP vaccination. Kidney proteins from cadaveric cats were extracted and immunized into rabbits using Montanide as the adjuvant. Based on enzyme-linked immunosorbent assay measurement, all immunized rabbits produced high levels of anti-cat kidney antibodies and some began to produce antibodies as early as 2 weeks after immunization. Immunofluorescence staining of rabbit sera showed kidney-bound antibodies in glomerulus, Bowman's capsule, apical surface of the proximal convoluted tubule, peritubular surface, and interstitial cells. Western blot analysis of cat kidney proteins revealed molecular weights (M.W.) of 72, 55, 47, and 31 kDa, while binding to the CRFK cell proteins was observed at M.W. of 43 and 26 kDa. The antibody that recognized the 47 kDa protein was similarly detected in cats with autoantibody presence after FVRCP vaccination. The kidney-bound antibody profile at different time points and its patterns in rabbits could be used as a model for the study of autoantibody to cat kidney in feline chronic kidney diseases.

Analysis and design of maxwell-based integral slot permanent magnet synchronous motor

[J].

DOI:10.4142/jvs.2019.20.e73

URL

PMID:31775199

[本文引用: 3]

Chronic kidney disease is considered to be most common in geriatric domestic cats. It has been reported that the feline viral rhinotracheitis, calicivirus, and panleukopenia (FVRCP) vaccine prepared from the Crandell-Rees feline kidney (CRFK) cell line can induce cross-reactions of antibodies with feline kidney tissues. As an anti-cat kidney antibody was not available commercially for this study of autoantibody in cats, the purpose of this study was to produce anti-cat kidney antibody in rabbits for further study of autoantibody in cats after FVRCP vaccination. Kidney proteins from cadaveric cats were extracted and immunized into rabbits using Montanide as the adjuvant. Based on enzyme-linked immunosorbent assay measurement, all immunized rabbits produced high levels of anti-cat kidney antibodies and some began to produce antibodies as early as 2 weeks after immunization. Immunofluorescence staining of rabbit sera showed kidney-bound antibodies in glomerulus, Bowman's capsule, apical surface of the proximal convoluted tubule, peritubular surface, and interstitial cells. Western blot analysis of cat kidney proteins revealed molecular weights (M.W.) of 72, 55, 47, and 31 kDa, while binding to the CRFK cell proteins was observed at M.W. of 43 and 26 kDa. The antibody that recognized the 47 kDa protein was similarly detected in cats with autoantibody presence after FVRCP vaccination. The kidney-bound antibody profile at different time points and its patterns in rabbits could be used as a model for the study of autoantibody to cat kidney in feline chronic kidney diseases.